Diving Into the Depths: Unveiling the Secrets of Submersible Pumps

Are you ready to dive into the world of submersible pumps? In this article, we will explore the secrets behind these powerful machines that work tirelessly beneath the water’s surface. Whether you’re searching for a reliable way to drain a flooded basement or in need of pumping solutions for major construction projects, pump submersible technology has become indispensable in various industries.

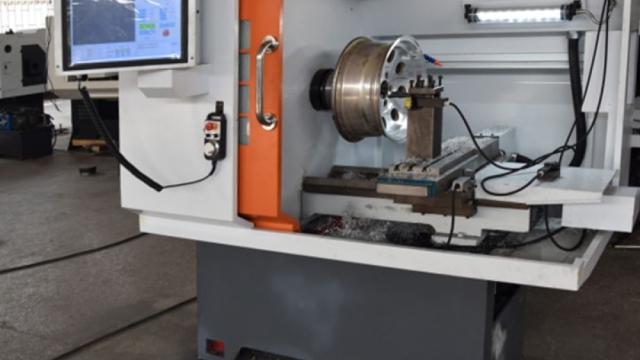

One reputable manufacturer in this field is Taian OCEAN Pump Co., Ltd., and their online platform, slurrypumpdm, is a hub for heavy-duty submersible pumps. With their extensive expertise and dedication to engineering top-notch products, they have gained a reputation for being a go-to resource for businesses worldwide.

In the following sections, we will dive deeper into the workings of submersible pumps, exploring their design, applications, and benefits. So, let’s gear up and get ready to unravel the mysteries of pump submersible technology!

Types of Submersible Pumps

Submersible pumps, as the name suggests, are specially designed to be immersed in water or other liquids for efficient pumping. They are widely used in various industries and applications to handle different types of fluids. In this section, we will explore the main types of submersible pumps commonly used today.

-

Utility Submersible Pumps: Utility submersible pumps are versatile pumps used for a wide range of applications. They are often used for draining flooded areas, such as basements or construction sites, as well as for removing water from swimming pools or ponds. These pumps are typically compact, portable, and easy to use, making them popular among homeowners and contractors alike.

-

Sewage Submersible Pumps: Sewage submersible pumps are specifically designed to handle wastewater and sewage containing solid particles. They are commonly used in residential, commercial, and industrial settings to pump sewage from toilets, basements, or underground storage tanks. These pumps are equipped with heavy-duty impellers to effectively handle solids and prevent clogging.

-

Borehole Submersible Pumps: Borehole submersible pumps are primarily used for extracting water from deep wells or boreholes. They are specially designed to deliver water from great depths, often used in applications such as irrigation, water supply for residential or commercial buildings, and public water distribution systems. Borehole pumps are known for their efficiency and reliability in delivering water over long distances.

With advancements in technology, there are several other specialized types of submersible pumps available in the market today. Each type is designed to cater to specific needs and requirements in different industries. By understanding the different types of submersible pumps, users can choose the most suitable pump for their specific applications and ensure optimal performance.

Applications and Benefits

Submersible pumps offer a wide range of applications and benefits that make them a reliable and versatile tool in various industries. From dewatering flooded areas to extracting water from deep wells, these pumps play a crucial role in many operations.

One of the key applications of submersible pumps is in the field of agriculture. These pumps are used to efficiently irrigate large tracts of land, ensuring that crops receive the right amount of water to thrive. By submerging the pump directly in water sources such as rivers or ponds, farmers can minimize energy loss and maximize water delivery to their fields.

Another area where submersible pumps excel is in sewage and wastewater management. These pumps are designed to handle solids and liquids, making them ideal for transferring sewage or draining flooded areas. Their ability to operate in submerged conditions enables them to efficiently pump out water from basements, construction sites, or other locations where water accumulation can be a problem.

In the mining industry, submersible pumps are commonly used for dewatering deep underground mines. These pumps can handle highly abrasive and corrosive slurries, ensuring a continuous and reliable extraction process. Their robust construction and ability to withstand challenging environments make them indispensable tools for extracting valuable minerals from the earth.

In summary, submersible pumps offer a multitude of applications and benefits across various industries. Whether it’s for agricultural irrigation, sewage management, or mining operations, these pumps provide efficient and reliable solutions in challenging environments. Their ability to operate while submerged makes them an invaluable tool for tackling water-related tasks with ease.

Factors to Consider Before Choosing a Submersible Pump

When selecting a submersible pump, there are several crucial factors that need to be carefully considered. By taking these factors into account, you can ensure that you choose a pump that is best suited for your specific needs. Let’s dive into these important considerations below.

-

Application: The first factor to consider is the application for which you require the submersible pump. Different pumps are designed to handle various tasks such as dewatering, drainage, slurry pumping, or wastewater treatment. Understanding the specific application will help you narrow down your options and select a pump that is capable of efficiently handling the required task.

-

Flow Rate and Head: The flow rate and head are important hydraulic parameters to consider when choosing a submersible pump. The flow rate refers to the volume of fluid that needs to be pumped, while the head represents the vertical distance or pressure the pump needs to overcome. It is crucial to match the pump’s performance characteristics, especially the flow rate and head, with the requirements of your application to ensure optimal functionality.

-

Pump Construction and Materials: The construction and materials of the submersible pump play a vital role in its durability and longevity in harsh operating conditions. Factors such as the pump’s casing, impeller, and motor should be considered. Materials like cast iron, stainless steel, or high-grade plastics are commonly used in submersible pumps and offer varying levels of corrosion resistance and strength. Selecting the right construction and materials will help ensure the pump can withstand the demands of your specific application.

By carefully considering these factors – the application, flow rate and head, and pump construction and materials – you can make an informed decision when choosing a submersible pump. Selecting a pump that aligns with your specific requirements will help you maximize efficiency, minimize downtime, and ensure the successful operation of your pumping system.